Our products incorporating Tsubaki technology play an important role in multiple processes on noodle production lines as well.

Noodle Making

Mixer and Roller

Dough is made using a machine called a mixer that stirs wheat flour, water, salt, and other ingredients. A roller is used in the process that spreads this dough into a thin sheet. The dough is spread gradually to make springy noodles.

-

Knead the dough

-

Spread dough into a thin sheet

-

Slit noodles (Slitter)

-

Steam noodles (Steamer)

-

Cardboard stacker

-

Transfer

-

Pack cups (Packer)

-

Put noodles into cups

-

Accumulate

-

Hot air dry

(for non-fried noodles)

-

Deep fry and dry

(for fried noodles)

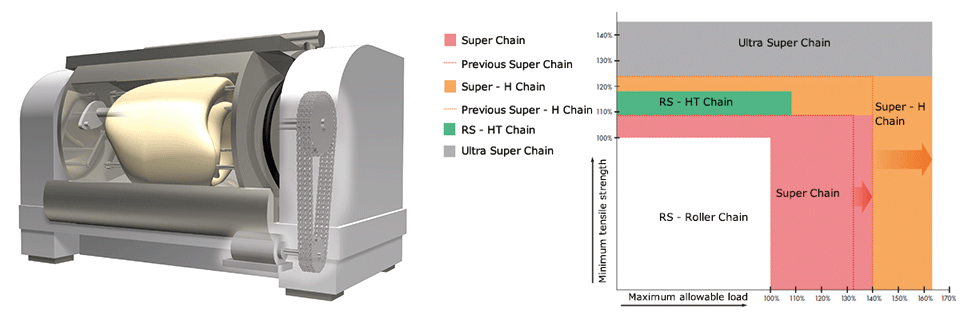

Heavy Duty Drive Chains and Sprockets

Heavy Duty Drive Chains enable downsizing thanks to a higher allowable load than standard roller chains, and realize more compact equipment even in narrow spaces.

We also offer a line-up of Tough Tooth Sprockets optimal for use with Heavy Duty Chains.

Minimum tensile strength and maximum allowable load, with RS Roller Chain as our benchmark at 100%

For more details on Heavy Duty Chains

Click here for more details on sprockets for Heavy Duty Chains

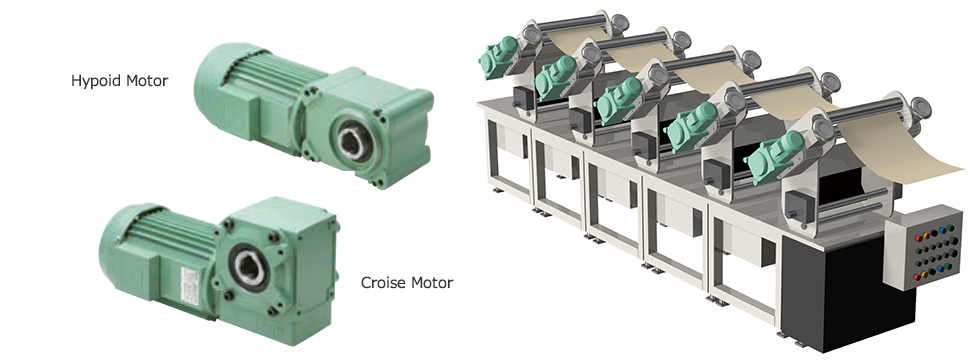

Reducer

Tsubaki’s reducers are used to drive mixers and rollers as our reducers can satisfy a wide range of needs.

Small Size Gear Motor

Various gear motors are used in the drive of the roller that spreads noodles in a thin sheet.

For more details on Hypoid Motor

For more details on Croise Motor

Toward a Sustainable Society

The Tsubaki Group is engaged in the “art of moving” and aims to provide value that exceeds expectations

to become a company that continues to be needed by society.